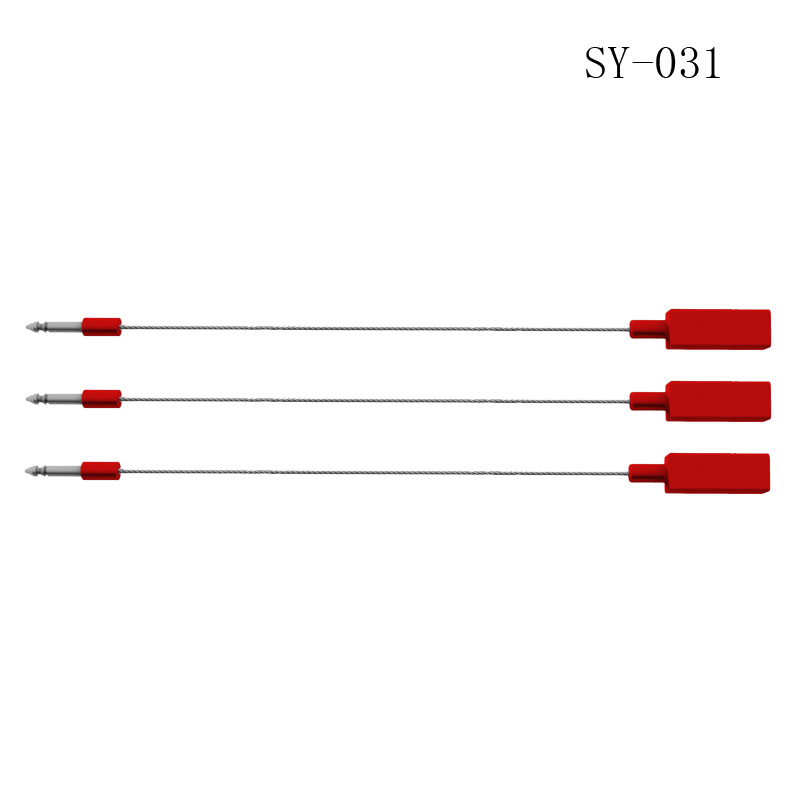

Customized Numbered Disposable Self-Lock Tamper Evidence Pull Tight Cable Tie Security Plastic Seal SY-031

Features

● Hardened carbon steel lock body with zinc chromate finish & high strength

● High-impact ABS plastic coating for visible tamper evidence

● Self-locking system easily to lock by hand

● Standard exposed cable length of 25cm, meantime with adjustable cable length

Customized Options

● Customer name, logo, sequential numbers and barcode (Hot Stamping / Laser Marking)

● Standard colors of white, yellow or other available customized colors

● Customized cable length available upon request

Applications

● Security → Doors of trailers and trucks, Cars, Vans, Tankers, Storage cabinets, Pipelines, High value or dangerous cargo

● Industries → Transportation, Power companies, Chemicals, Military, Banking, Customs, Healthcare, Food and beverage

Instructions for Use

● Loop the cable through the item to be sealed.

● Insert and pull the cable through the locking chamber.

● Pull the cable all the way through the body until the item is tightly sealed.

● Verify that the security seal is sealed.

● Record the seal number to control security.

Removal

● By cable cutters

Specifications

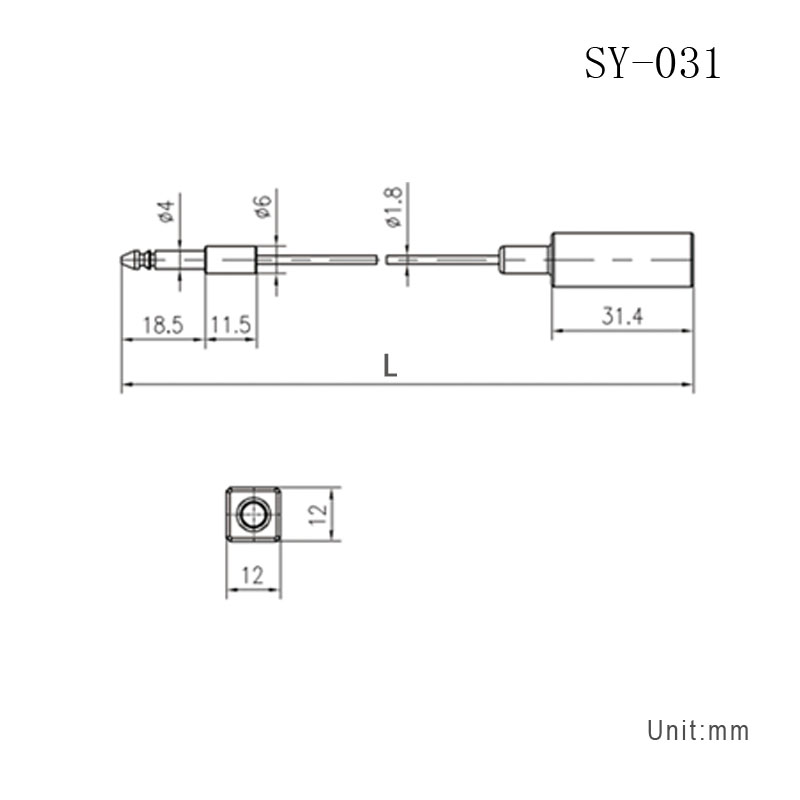

| Material | Lock Body → Galvanized carbon steel & ABS coating

Cable → Galvanized steel wire |

| Size | Check the above drawing |

| Colors | White (Standard), Yellow (Standard) or other available colors |

| Printing Method | Hot stamping or Laser marking |

| Customization | Printing → Customer name, logo, sequential numbers and barcode (Laser) |

| Strength Category | ≥ 3.5KN (Security Seal, ISO) |

Order Online - www.chnseal.com or call +86-559-5299999 or email chnseal@chnseal.com

It plays a key role in controlling risks, reducing losses and preventing risks in logistics transportation, container customs and various security protection industries. Therefore, customers should pay special attention to the following factors when purchasing seal lock products:

1. Look at the color and buy Plastic Cable Seal: the color of high-quality Plastic Cable Seal will not look very bright and conspicuous. Because the color of high-quality plastic seal is not oil, but after deep processing, the color is integrated into the plastic, so that the developed plastic seal will not scratch or fade. It's very textured.

2. Compare the weight to buy Plastic Cable Seal: a high-quality plastic seal is relatively heavy. Why? Because there are many technological processes to be injected into the development of real Plastic Cable Seal, so there are more materials to be added. Therefore, when purchasing, we must look at the weight.

3. To select manufacturers with guaranteed quality and reputation (products without quality and reputation assurance cannot be locked tightly and play an anti-theft role), manufacturers must standardize management in quality control process, raw material procurement, product testing and other links. It has advanced production, inspection and test equipment and strong technical support

Technical strength and R & D ability.

4. Sign the contract before ordering. The manufacturer is required to promise not to provide the container seal number with the same identification and number to the third party. The steel wire seal number is very important, and sometimes a confidentiality agreement must be signed.

5. Try not to use products of the same size / color produced by multiple manufacturers (easy to be copied and imitated, which brings convenience to some illegal attempts, thus losing the real sense of anti-counterfeiting). Products that have been circulating in the market for too long should not be selected. At the same time, manufacturers with technical advantages and R & D capabilities generally develop more selected products regularly to meet the needs of the market.

Any product has a certain manufacturing cost, and some products with low prices must be paid attention to when purchasing (some manufacturers reduce costs by cutting corners).

6. Inspect the actual production scale and actual production capacity of the manufacturer to ensure timely and rapid supply.